About to Environment friendly Biodegradable Plastic Materials EPOM

Environment friendly Biodegradable Plastic Materials EPOM

Stone Ore Powder

Characteristic Modified

EPOM is a stone ore powder that undergoes physical engineering and chemical transformations …to change its inherent molecular properties and structure, making plastic products after being discharged into the environment. In addition, after a period of time, the complete decomposition effect will be achieved.

EPOM has good adhesion, biocompatibility, biodegradability, non-toxicity and exceptional absorbency.

Eco-Friendly,

Reduce Plastic Waste

NO' pollution to the environment and 'NO' burden to the earth. The optimized biodegradable … plastic material EPOM meets the current urgent need in solving the problem of non-biodegradable plastic waste pollution, helping their living environment to stay away from the environment. waste pollution from common plastic products.

Using Conventional Production

Machinery and Equipment

The stone powder has been modified but has the characteristics of plastic and the … material should be suitable for producing plastic products with current popular methods such as blowing film; extrusion, hollow casting, bottle blowing, spinning without changing production conditions and equipment.

Non-toxic, compostable, low carbon emissions, energy saving are the advantages of this product.

Stone Ore Powder

Characteristic Modified

EPOM is a stone ore powder that undergoes physical engineering and chemical transformations …to change its inherent molecular properties and structure, making plastic products after being discharged into the environment. In addition, after a period of time, the complete decomposition effect will be achieved.

EPOM has good adhesion, biocompatibility, biodegradability, non-toxicity and exceptional absorbency.

Eco-Friendly, Reduce Plastic Waste

NO' pollution to the environment and 'NO' burden to the earth. The optimized biodegradable … plastic material EPOM meets the current urgent need in solving the problem of non-biodegradable plastic waste pollution, helping their living environment to stay away from the environment. waste pollution from common plastic products.

Using Conventional Production, Machinery and Equipment

The stone powder has been modified but has the characteristics of plastic and the … material should be suitable for producing plastic products with current popular methods such as blowing film; extrusion, hollow casting, bottle blowing, spinning without changing production conditions and equipment.

Non-toxic, compostable, low carbon emissions, energy saving are the advantages of this product.

Advantages & Properties of Biodegradable Plastic Materials EPOM

Characterized Stone Ore Powder

Not PLA starch or common stone powder additive.

Decomposed in Natural Environment

Tuỳ theo tính chất của mỗi loại sản phẩm, sau khi sử dụng và bị thải ra môi trường bên ngoài có thể phân rã và phân huỷ trong điều kiện môi trường tự nhiên mà không gấy độc hại. Là một loại nguyên vật liệu hoàn toàn mới thân thiện với môi trường.

No Toxic Substances

No lead, mercury, cadmium and plasticizer, no poison after burning, is a degradable environmental protection material.

Small, Fine Particle Size

Nano particles from stone ore powder have been modified to have small, fine molecules that do not damage the blown head and screw of the machine.

'Low Production Temperature

Yêu cầu nhiệt độ thấp hơn so với khi sản xuất với nguyên liệu nhựa thông thường, vì thế đạt hiểu quả trong việc tiết kiệm điện và giảm carbon bảo vệ môi trường.

Zero Waste

In the production process there is no waste water, no emissions, no waste, no bleach, and is 100% recyclable.

Characterized Stone Ore Powder

Not PLA starch or common stone powder additive.

Decomposed in Natural Environment

Depending on the nature of each product, after being used and discharged into the outside environment, … it can decompose and decompose in natural environmental conditions without causing toxicity. It is a completely new kind of environmentally friendly material.

No Toxic Substances

No lead, mercury, cadmium and plasticizer, no poison after burning, is a degradable environmental protection material.

Small, Fine Particle Size

Nano particles from stone ore powder have been modified to have small, fine molecules that do not damage the blown head and screw of the machine.

'Low Production Temperature

Requires a lower temperature than when producing with ordinary plastic materials, so it is effective … in saving electricity and reducing carbon to protect the environment.

Zero Waste

In the production process there is no waste water, no emissions, no waste, no bleach, and is 100% recyclable.

Characterized Stone Ore Powder

Not PLA starch or common stone powder additive.

Decomposed in Natural Environment

Depending on the nature of each product, after being used and … discharged into the outside environment, it can decompose and decompose in natural environmental conditions without causing toxicity. It is a completely new kind of environmentally friendly material.

No Toxic Substances

No lead, mercury, cadmium and plasticizer, no poison after burning, is a degradable environmental protection material.

Small, Fine Particle Size

Nano particles from stone ore powder have been modified to have small,… fine molecules that do not damage the blown head and screw of the machine.

'Low Production Temperature

Requires a lower temperature than when producing with ordinary plastic materials, so it is effective … in saving electricity and reducing carbon to protect the environment.

Zero Waste

In the production process there is no waste water, no emissions, no waste, no bleach, and is 100% recyclable.

EPOM ARE POLIORING IN THE USE OF THIS MATERIAL

Characterized Stone Ore Powder

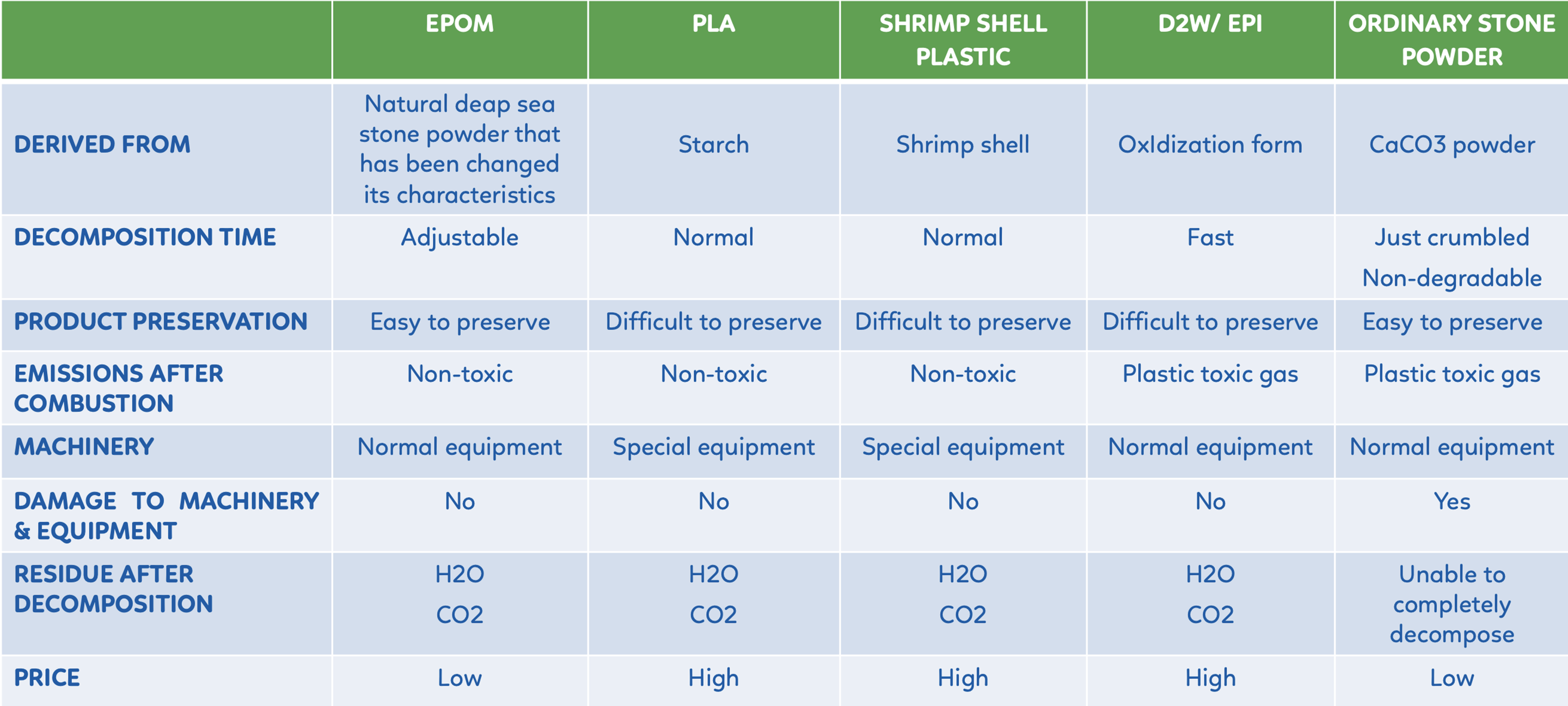

| EPOM | PLA (Corn Starch) | SHRIMP PLASTIC | D2W / EPI | Ordinary stone ore powder | |

|---|---|---|---|---|---|

| DERIVED | Natural deap sea stone powder that has been changed its characteristics | Starch | Shrimp shell | OxIdization form | CaCO3 Powder |

| DIFFERENCE TIME | Adjusted | Normal | Normal | Fast | Just crumbled Non-degradable |

| PRODUCT PRESERVATION | Easy to preserve | Difficult to preserve | Difficult to preserve | Difficult to preserve | Easy to preserve |

| EMISSIONS AFTER COMBUSTION | Non-toxic | Non-toxic | Non-toxic | Plastic toxic gas | Plastic toxic gas |

| EQUIPMENT OF PRODUCTION | Normal equipment | Special equipment | Special equipment | Normal equipment | Normal equipment |

| DAMAGE TO MACHINERY AND EQUIPMENT | No | No | No | No | Yes |

| REFERENCES AFTER COMPOSITION | H2O CO2 |

H2O CO2 |

H2O CO2 |

H2O CO2 |

Can't completely decompose |

| PRICE | Low | High | High | High | Low |

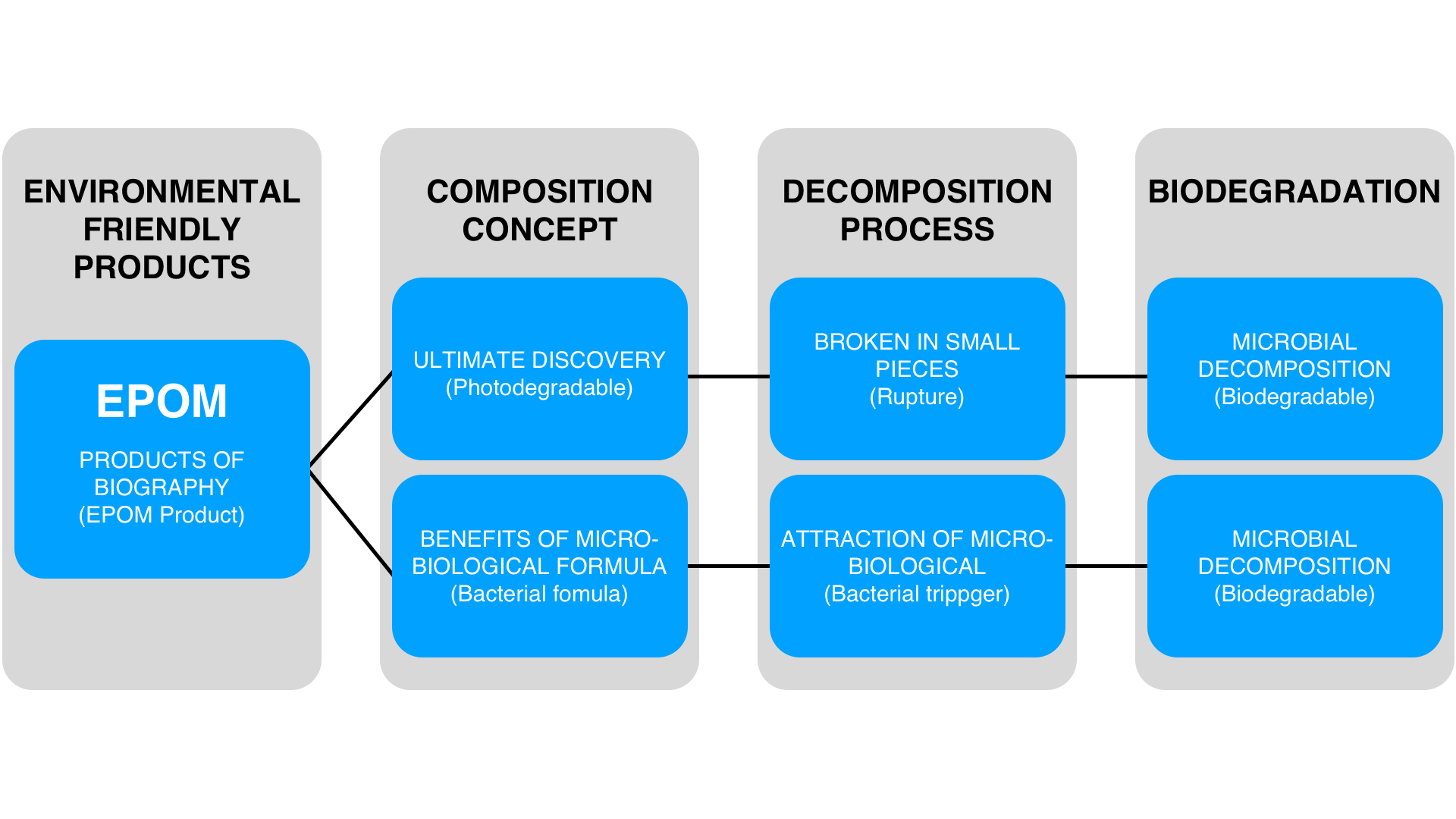

EPOM Decomposition Process

The decomposition process is divided into two stages:

- Decomposes under the action of ultraviolet rays.

- Decomposed under the action of microorganisms.

The chain structure of the EPOM biodegradable material is closely linked to the Carbon (C) and Hydrogen (H) radicals, creating a bridging chain that forms the macromolecular block.

Decomposes under the Impact of Ultraviolet Rays

EPOM materials are mainly composed of modified rock ore powder. Incorporating rock ore powder into plastic products, after a period of time under the influence of ultraviolet rays, the plastic molecules decrease and the structure is broken, from which the product is broken into small pieces. . And this is also called the concept of decay.

Completely Decomposes Under Microbial Action

Specially formulated ingredients contain substances that are highly favored by soil microorganisms. Along with changing the molecular structure of rock ore powder by physical and chemical methods, the structure of the carbon and hydrogen bonds is changed in order, changing the inherent properties of the resin, from that plastic products can attract large amount of microorganisms to rodents and decomposition occurs, and that is also the concept of biodegradation of EPOM.

ENVIRONMENTAL

FRIENDLY

PRODUCTS

EPOM

PRODUCTS OF

BIOGRAPHY

(EPOM Product)

COMPOSITION

CONCEPT

ULTIMATE DISCOVERY

(Photodegradable)

BENEFITS OF MICRO-

BIOLOGICAL FORMULA

(Bacterial fomula)

DECOMPOSITION

PROCESS

BROKEN IN SMALL

PIECES

(Rupture)

ATTRACTION OF MICRO-BIOLOGICAL

(Bacterial Trippger)

EPOM

BIODEGRADATION

MICROBIAL

DECOMPOSITION

(Biodegradable)

MICROBIAL

DECOMPOSITION

(Biodegradable)

Residues In Soil After Decomposition

The EPOM product, after being decomposed under the action of microorganisms, the residue left in the soil will be 3 large elements CaO (lime) + CO2 (carbonate gas) + H2O (water), absolutely no pollute the environment, do not damage the ecological environment, is the solution to solve the problem of non-biodegradable millennia of plastic products.

As a rare degradable material today, the final reaction chain, when completely decomposed in the soil, converts to CaO + CO2 + H2O.

Absorb Heavy Metals In Soil

EPOM can absorb and decompose heavy metal compounds that are residues of pesticides and chemical fertilizers after a long time of use in the cultivation process.

Minimizing a large amount of heavy metal residues in the soil causing soil pollution.

Facebook

Facebook